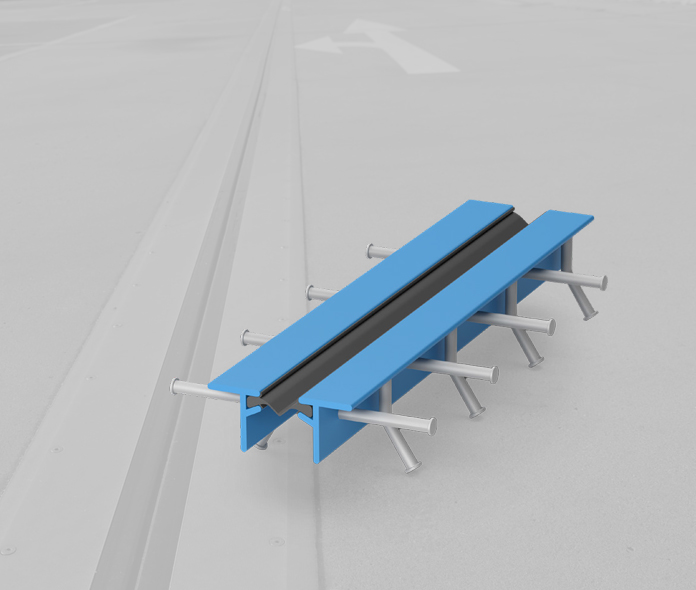

HDPE SWC Sheathing Ducts

Kataria Single Wall Corrugated (SWC) pipes serve as widely utilized ducts for bonded post-tensioning tendons in prestressed concrete applications. These pipes effectively address the challenge of corrosion, a significant threat to reinforced concrete structures. Customizable to meet National, International, or customer-specific technical specifications, Kataria SWC pipes offer a versatile solution for diverse construction requirements.

HDPE SWC Sheathing Ducts

Technical Specification

| Sr.No. | Duct (code) | ID Inside Diameter (mm) | OD Outside Diameter (mm) | Wall Thickness (mm) | Compatible Anchor Cones |

|---|---|---|---|---|---|

| 1 | KTD50 (R) | 39 | 50 | 2E0.3 | KTH 4KT13 |

| 2 | KTD63 (R) | 50 | 63 | 2.3 ± 0.3 | KTH 7KT13/ KTH 4KT15 |

| 3 | KTD78 (R) | 63 | 78 | 2.3 ± 0.3 | KTH 7KT13/ KTH 4KT15 |

| 4 | KTD92 (R) | 75 | 92 | 2.3 ± 0.3 | KTH 12KT13/ KTH 7K115 |

| 5 | KTD97 (R) | 85 | 97 | 2.3 ± 0.3 | KTH 19KT13/ KTH 12K115 |

| 6 | KTD110 (R) | 105 | 120 | 2.3 ± 0.3 | KTH 27KT13/ KTH 19KT15 |

HDPE Material Specification

| Density (IS 2530) | 094-096gm/CmA3 at 3°C |

| Melt Flow Index (15) ASTM D 1238 | 10gm/10Min |

| Coefficient of thermal expansion for 20°C-80°C | 15x10A4kj |

| Shore Hardness D (BS EN ISO 2039-1) | 3sec-60min 15sec-58min |

| Elongation at yield (BS EN ISO 527-3) | 7% minimum |

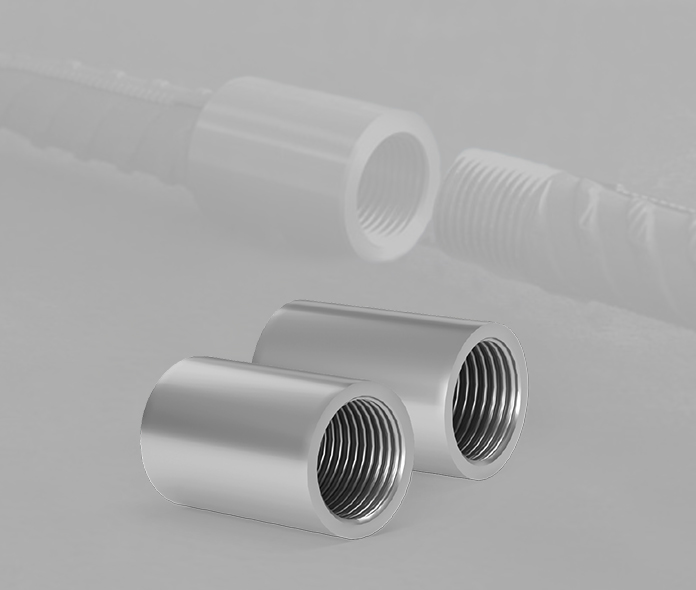

SWC Duct Joints & Fittings

- Couplers Snap-fit / Heat Shrink

- Tee

- Grout Vent

In-House Testing Facilities

(As Per IRC: 18-2000/FIB Bultein No 7)

- Workability Test

- Transverse Load Rating Test

- Tension Load Test

- Water Loss Test

Benefits of SWC Sheathing Ducts

- Superior Corrosion Protection

- Provides Solid Bonding with Concrete

- High Stiffness, Flexibility and Light Weight

- Less Prestressed Losses i.e., Friction and Wobble

- Chemical Inert

- Available in Various Length Options

- Speedy Installation due to Fewer Joints

- Produced with High Quality Raw Material

- Consistent Quality

- Latest Technology Machinery

- In-house Well-equipped Testing Facility

SWC Ducts manufacturing confirms to

- FIB Bulletin No. 7

- IRC Specification

- NPCIL Specifications

- Addendum and corrigendum IRS slip No 4, Railway concrete Bridge code 1957

- As per customer’s specific technical specification

Approved by

National Highway authority of India(NHAI)

Various Metro Corporations

Various State Road Development Authorities

Others....

Tested and passed by 3rd Party Test Laboratories

Indian Institute of Technology (IIT) – Chennai

Anulab – Agra